Rotary Table Two

Package Size 550.00cm * 183.00cm * 210.00cm Package Gross Weight 9500.000kg 1.Picture 2. Specifications 3. Advantage a.

Description

Basic Info.

| Model NO. | HXSM200 |

| Structure | Horizontal |

| Plastic Type | PS, ABS, PP, HDPE, PA, PA, EVA |

| Plasticizing Way | Screw Type |

| Clamping Way | Hydraulic & Mechanical |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Injection Weight | 120 G |

| Space Between Tie Bar | 840*520 mm |

| Moving Mould-Plate Stroke | 500 mm |

| After Sales Service | Engineers Avaiable to Service Machine |

| Injection Capacity in Theory | 132 Cm3 |

| Voltage | 380V/50Hz, According to Countries |

| Transport Package | Standard Package |

| Specification | 5.5*1.83*2.1 M |

| Trademark | Highsun |

| Origin | China |

| HS Code | 8477101090 |

| Production Capacity | 7000 Sets / Year |

Packaging & Delivery

Package Size 550.00cm * 183.00cm * 210.00cm Package Gross Weight 9500.000kgProduct Description

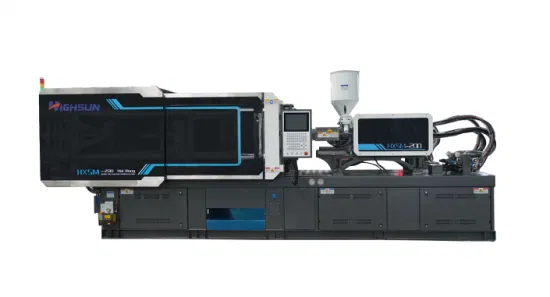

1.Picture

2. Specifications

| MODEL:HXSM200 | ||||||

| TECHNICAL PARAMETER TABLE | A | B | C | D | ||

| INJECTION UNIT | SCREW DIAMETER | mm | 28 | 32 | 36 | 40 |

| SCREW L/D RATIO | L/D | 22 | 23.6 | 21 | 21 | |

| INJECTION CAPACITY IN THEORY | cm3 | 80 | 132 | 167 | 207 | |

| INJECTION WEIGHT(PS) | g | 72 | 120 | 152 | 188 | |

| oz | 2.5 | 4.2 | 5.3 | 6.6 | ||

| INJECTION PRESSURE | MPa | 215 | 271 | 214 | 174 | |

| INJECTION RATE | g/s | 105 | 83 | 106 | 131 | |

| PLASTICIZING CAPACITY | g/s | 9 | 11 | 13.9 | 18.4 | |

| SCREW SPEED | rpm | 300 | ||||

| CLAMPING UNIT | CLAMPING FORCE | KN | 2000 | |||

| MOVING MOULD-PLATE STROKE | mm | 500 | ||||

| MAX. MOULD HEIGHT | mm | 500 | ||||

| MIN. MOULD HEIGHT | mm | 180 | ||||

| SPACE BETWEEN TIE-BARS (W×H) | mm | 840*520 | ||||

| HYDRAULIC EJECTOR FORCE | mm | 31 | ||||

| HYDRAULIC EJECTOR STROKE | KN | 110 | ||||

| EJECTOR NUMBER | n | 3*2 | ||||

| OTHERS | PUMP PRESSURE | MPa | 16 | |||

| MOTOR /DRIVING POWER | KW | 15+15 | ||||

| HEATING CAPACITY | KW | 10.5 | ||||

| MACHINE DIMENSION (L×W×H) | m | 5.5*1.83*2.1 | ||||

| MACHINE WEIGHT | t | 9.5 | ||||

| OIL TANK CAPACITY | L | 410 | ||||

3. Advantage

a. SUPER ENERGY SAVING

Output power varies with the load, and no energy is wasted. In the holding pressure phase, the servo motor willreduce speed, with low energy consumption; during the cool-down period, the motor does not work, with zero power consumption. Compared with the ordinary injection molding machines, it can save 20%-80% of the power.

b. HIGH PRECISION AND HIGH STABILITY

Equipped with the precise pressure sensor and rotary encoder, it can respectively monitor and feed back on flow and pressure. Based on the feedback, the high performance synchronous servo motor will adjust flow and pressure accordingly by changing the speed and torque. The closed-loop control can ensure the stability of product quality.

c. HIGH RESPONSE AND HIGH EFFICIENCY

The driving system responses with high sensitivity . It takes only 0.05 seconds to reach maximum value. The response speed is much faster than the ordinary injection molding machines. In that way, it significantly shortens the cycle time and increases the production efficiency.

4. Product Produced by Injection Molding Machine

5. Factory

China top 1 plastic injecion molding machine

a. Honored with "Top 3" manufacturer of comprehensive strength by NBPMA over the past decade.

b. Established in 1973. Concentrate on Injection Molding field more than 50 years.

c. It covers an area of 1.2 million square feet.

d. Sold to more than 40 countries around the world.

e. Annual output more than 7000sets,ensuring faster delivery time.

f. Worldwide sales reached 130 million US dollars, exports maintain steady growth.

Prev: Rotary Table Vertical Injection Molding Machine 85 Tons

Next: Factory Wholesale Used Large 800ton Horizontal Injection Molding Machine with Low Price

Our Contact

Send now